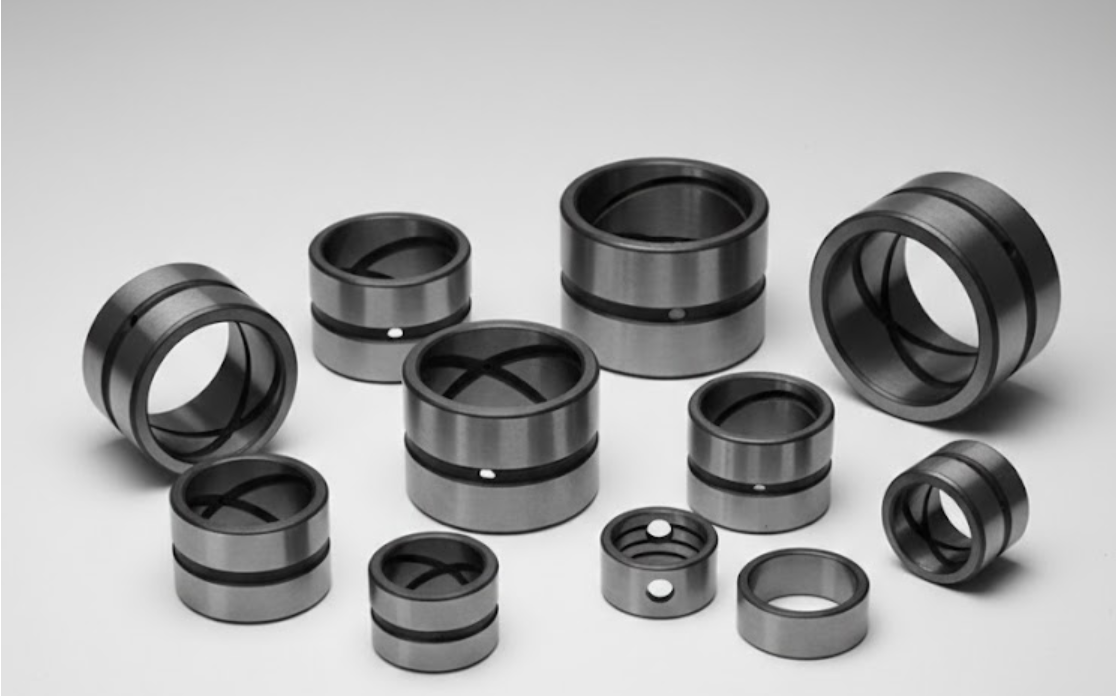

Premium Steel Groove Bushings: Engineered for High-Strength Performance

Maximize the durability and reliability of your heavy-duty machinery with our precision-engineered Steel Groove Bushings. In extreme-pressure or high-impact environments, standard bushings can suffer from premature galling and seizure. Our custom-machined lubrication grooves address this by maintaining a robust, pressurized lubricant barrier between the pin and the bushing wall.

Why Choose Steel Grooved Bushings?

The primary advantage of steel-based bushings is Structural Integrity and Wear Resistance. By integrating specialized pathways into high-grade carbon or alloy steel, our grooved bushings:

Enhance Load Capacity: Support significantly higher PSI loads compared to softer alloys.

Optimize Surface Hardness: Often case-hardened to prevent surface deformation while maintaining lubrication flow.

Extend Maintenance Intervals: Improved grease retention means less downtime for manual re-lubrication.

Strategic Groove Patterns & Their Applications

We offer a comprehensive range of industry-standard and custom patterns designed to optimize the lifespan of your steel-on-steel or steel-on-hardened-pin connections:

|

Groove Pattern |

Best For |

Functional Benefit |

|

Straight / Circular |

Basic lubrication |

Provides a steady reservoir for oil or grease in unidirectional rotation. |

|

Figure 8 / Double 8 |

High-load oscillation |

Ideal for pivot points where the pin moves back and forth under heavy stress. |

|

Loop / Double Loop |

Sealed environments |

Maximizes lubricant retention within the bearing to prevent dry spots. |

|

Spiral / Helical |

High-speed rotation |

Uses the shaft's rotation to actively "pump" lubricant across the entire bore. |

|

Extended Grooves |

Contaminated zones |

Designed to flush out grit and old grease through the ends of the bushing. |

Typical Applications

Our grooved steel bushings are the critical components for equipment operating under harsh conditions, including:

Heavy Construction: Bucket pins, blade pivots, and undercarriage assemblies.

Waste Management: Compactor linkages and lift-arm pivot points.

Material Handling: Conveyor rollers and high-capacity forklift masts.

Off-Road Equipment: Suspension bushings for logging and earthmoving vehicles.

Expert Guidance & Technical Support

If you have questions regarding material grades (such as 4140 or 1045 steel), heat treatment specifications, or pattern selection, we are here to help. Please submit your inquiry via our website contact form or email us directly at [email protected] for a detailed technical consultation.

Pls Scan our customer service whatsapp

Pls Scan our customer service whatsapp